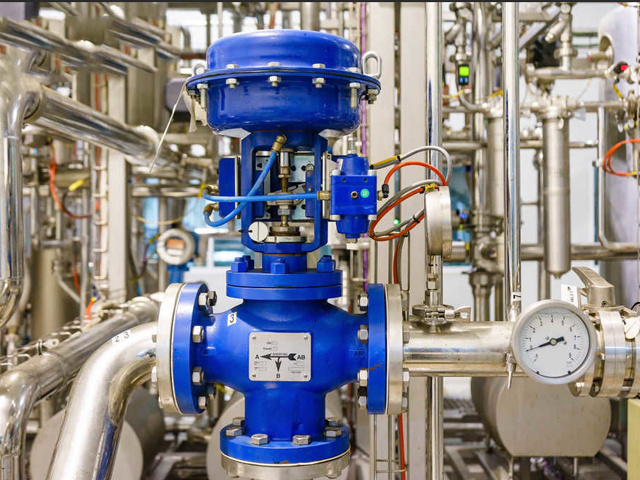

Product Features of Nylon Pneumatic Butterfly Valve

Release time: 2019-03-15

Product features of Long pneumatic butterfly valve:

1, the use of nylon pinless butterfly plate, with excellent wear reduction, self-lubrication, operating torque than ordinary pinned butterfly valve to reduce forty percent;

2, sealing surface wear resistance (nylon wear resistance is seven times that of copper), can significantly extend the service life of the butterfly valve, compared with the ordinary centerline butterfly valve, the service life can be significantly extended by three times;

3, nylon material without any toxicity, and antibacterial, anti-mold, in line with the growing importance of green environmental protection requirements;

4, nylon has excellent alkali and salt resistance, resistance to weak acid erosion, inert to organic compounds, wide range of adaptability;

5、Advanced pinless connection ensures complete isolation of the medium from the metal, which improves the reliability of the product and makes the butterfly valve simple to maintain;

6, the product and pipeline flange connection size in line with the existing butterfly valve products of various countries standards.

keywords:

Related News

How to extend the use cycle and stability of pneumatic ball valves

Pneumatic ball valves in industrial applications is a widely used type of general-purpose valves, the use of large quantities, consumption is also fast, the need for regular and reasonable maintenance and repair, so that the efficiency can be improved, the cost can be saved, and reduce the time of maintenance. How to make the pneumatic ball valve longer service life, stable performance, the following points need to pay attention to the factors: 1, before using the pneumatic valve debris and iron filings with water for cleaning. 2, pneumatic valve in the closed state, the valve will also have some residual media, to cut off the power supply and gas source and then clean up, the pressure in the valve body to be completely released. 3, the valve will generally use sealing materials to prevent leakage and wear, the need for regular cleaning of sealing materials into. 4, flange nuts and bolts should be fixed tight, in order to prevent uneven acceptance between the flange surface leads to gasket damage or rupture, resulting in the valve flange docking out of the media leakage. 5, if the valve is a long-term open-air work will lead to the valve and parts of the rust may make the valve can not be used normally, so the need for maintenance and testing, in order to ensure the stable operation of the performance.

View News