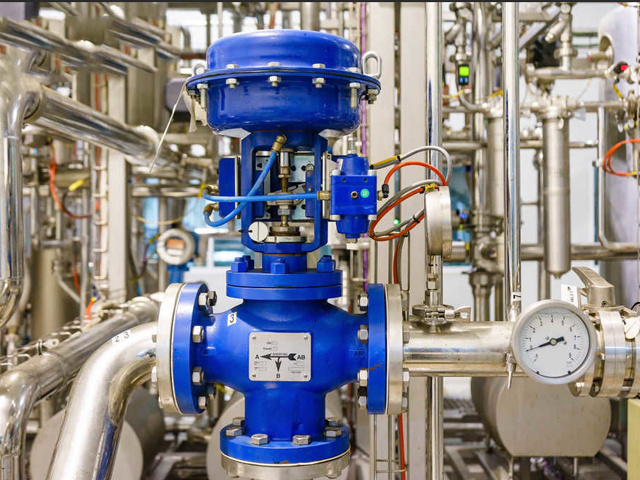

How AT pneumatic actuators should be maintained

Release time: 2019-03-15

How to maintain AT pneumatic actuator well?

1, AT pneumatic actuator and valve connection in accordance with ISO5211 standard, can be directly connected with the valve. It can also be connected with any valve through transition bracket and connector.

2, the installation must ensure that the pneumatic actuator and rotary axis and valve shaft coaxiality.

3、The inside of pipe joints and conduits should be cleaned and free of excess, dust and oil.

4, pneumatic actuators and solenoid valves, positioners, filters, pressure reducing valves, etc., can be connected by copper or nylon tube, in order to prevent dust and reduce noise, the exhaust port should be installed muffler or muffling throttle.

5, pneumatic actuator on the adjusting screw, you can micro-adjust the opening angle of the valve, after adjusting the nut must be locked.

6, after installation, the pneumatic actuator and the valve should be tested at the same time, the valve is pressurized to the rated pressure, the pneumatic actuator with a gas source pressure of 0.4 ~ 0.7MPa on the pneumatic actuator of the two air inlet switching inlet to observe the opening and closing of the valve should be rotating and flexible, no jamming phenomenon, and do repeated tests.

7, the installation of solenoid valve pneumatic actuator, debugging should be the first manual device (solenoid valve on the red button) tuning, and then power debugging.

8, AT pneumatic actuator should be regular maintenance and maintenance, regular pneumatic actuator with the use of air to the filter for draining, sewage, under normal circumstances, six-month inspection, an annual overhaul.

keywords:

Related News

How to extend the use cycle and stability of pneumatic ball valves

Pneumatic ball valves in industrial applications is a widely used type of general-purpose valves, the use of large quantities, consumption is also fast, the need for regular and reasonable maintenance and repair, so that the efficiency can be improved, the cost can be saved, and reduce the time of maintenance. How to make the pneumatic ball valve longer service life, stable performance, the following points need to pay attention to the factors: 1, before using the pneumatic valve debris and iron filings with water for cleaning. 2, pneumatic valve in the closed state, the valve will also have some residual media, to cut off the power supply and gas source and then clean up, the pressure in the valve body to be completely released. 3, the valve will generally use sealing materials to prevent leakage and wear, the need for regular cleaning of sealing materials into. 4, flange nuts and bolts should be fixed tight, in order to prevent uneven acceptance between the flange surface leads to gasket damage or rupture, resulting in the valve flange docking out of the media leakage. 5, if the valve is a long-term open-air work will lead to the valve and parts of the rust may make the valve can not be used normally, so the need for maintenance and testing, in order to ensure the stable operation of the performance.

View News